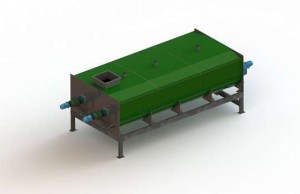

The B1400 Rocket Composting System was developed after the success of the larger B2500 system. The B1400 shares the same design principles and has a double “u” shaped shaft. The dual axle system allows for much greater performance and capacity than a single shaft structure, and also allows the unit to remove any inner axle struts, thus improving ventilation, there are no concerns about internal corners or parts that need maintenance or causing flow barriers.

The unit is mounted in load cells and the weight of the system is monitored continuously. When the software calculates that the unit is ready to unload the material, it deposits it into a stock carrier.

When the unit is configured with a hopper feed system, the unit recalculates the weights and communicates with the hopper system, requesting fresh material to be inserted. This discharge and recharging process is fully adjustable but typically the system will unload and call for material between 18-30 times a day without the need for any interaction with the operator.

The residence time in the container is about 6-8 days. If supplied as above, humidity & C: N ratios are constant and thermophilic temperatures of 55-65 ° C are observed for prolonged periods of 3-5 days at the center of the process. This ensures the efficient eradication of pathogens, thus allowing the composting of waste such as CAT3 meat, including catering waste.

Provided that the material mix and operator skill level are maintained, the maturation period for the final product before use can be only 2-3 weeks, which means that only a small outer container is required for storing and for the completion of the final product.

The system is specifically designed for low operator interaction, low maintenance requirements and low operating costs and is expected to use just 175kW of electricity per week.

The unit can be housed indoors or outdoors, requires a 400v / 3ph power supply and has standard infusion and air extraction equipment, temperature monitoring, internet access control for parameters and can be equipped with systems for multiple feed. (which may need cover / casing)

Its robust construction ensures long life and makes it capable of on-site processing of the following materials:

• Processed or raw meat and fish

• Cooked or raw fruits and vegetables

• Garden waste

• Animal impurities

• Sludge

TECHNICAL SPECIFICATIONS

| Length | 8670 mm |

| Width | 2900 mm |

| Height | 2620 mm |

| Capacity | 1,7 tn/day |

| Motor | 2 * 2.2 kW |

| Average Power Consumption | 175 kWh / week |

| User Interface | PLC, Ethernet, wireless |

| Temperature Recording | 8 channel recorder and software |

| Vessel Insulation | PIR BCO in thickness 50mm in the main container’s cover and on the roof |

| Installment | Outdoors, requires roof |

| Ventilation System | Fan 30 m^3 / hr with 190mb |

| Extraction Points | x3 |

The composting plant includes:

- Constant cylindrical construction, all components that come into contact with organic are made of 304SS.

- High torque gearbox with sliding ring and engine 2.2kW

- Floorboard control panel, housing communication devices, main power converters and PLC. PLC equipped with Ethernet for remote-controlled recording, monitoring and control. Touch screen on the outside of the housing to control the basic functions and connected components.

- 4 x PT100 compressors for temperature measurement of compost, 2 k-type temperature sensors for ambient air and for measuring the temperature of the exhaust air.

- Fully adjustable multiple air extraction unit, including 4 variable volume bulbs and a 0.25 kWW centrifugal fan with an external motor. It is possible to adjust the air intake to 4 different levels of composting. Connected to the PLC for easy control.

- Main chamber coated with plastisol and steel and high density thermal insulation.

- Thermally insulated inspection doors 50mm x 3 with insulated plates x 2

- Manual hopper

- Automatic extraction of the compost from the extraction point to a height of 60 cm.