Specifically designed for the safe and hygienic on-site processing of organic wastes, the A900 provides a sustainable solution for larger organisations or multi-site collections.

From the most widespread models of mechanical composting with capacity to manage up to 100 kg of biowaste per day. It is a frequent choice for the composting of biowaste in small tourist units, private schools and universities, while it can cover the needs of a small settlement.

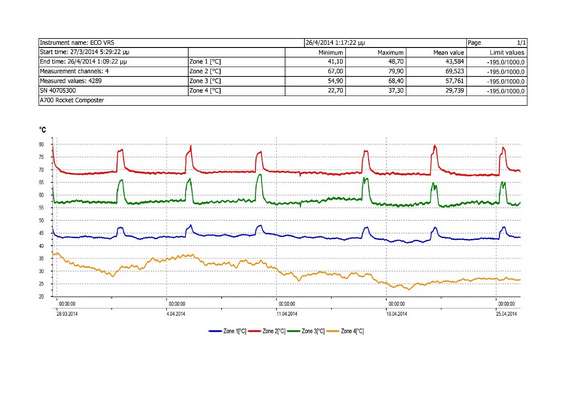

Like all models ROCKET® has an automatic temperature recording system in 4 levels of the enclosure. This ensures excellent monitoring of the composting process. Below you can see the thermograph we receive from the logger.

It has a dosing pump for the addition of water or other materials that help in composting. As in every composting unit it is necessary to have carbon in any form (sawdust, wood shavings, pellets, crushed wood, etc.). ).

Works with 220 V Supply and energy consumption is 26 KWh per week. Very low energy consumption is an important advantage over other technologies.

Available as a stationary organic waste solution with the facility for temperature recording and robust construction ensuring longevity, the Rocket® range of food waste treatment systems are suitable for the on-site processing of:

- Cooked & Uncooked Meat & Fish

- Cooked & Uncooked Fruit & Vegetables

- Garden Waste

- Animal Waste (including some types of bedding)

Currently in operation at a wide range of sites throughout the UK, the A900 Rocket® is saving on expensive organic waste disposal costs for many organisations including:

- ACS International Schools

- RHS Garden Rosemoor

- Regents College

- British Petroleum

- HM Prison Service

TECHNICAL SPECIFICATIONS

| Size (mobile) Length | 4000mm |

| Width | 1000mm |

| Height | 1900mm |

| Capacity | 215 Litres of food waste per day |

| *Optional: | Up to 650 litres per day (combined with Dehydra Dewaterer) |

| Motor | 0.75kW |

| Power Requirement | Single-phase 240-volt, one 13 or 16 amp plug socket |

| Average Power Consumption | 30 kWh+ per week |

| Heater Element | 2 X 1.0kW – Thermostatically controlled |

| Temperature Recording | 4 channel recorder and software |

| Air extraction | Included |

| Housing Requirement | Min 6 x 3m Under cover on hard standing (non-porous) |

| Options | Dehydra De-waterer package increases capacity to 5250 litres per week. Temperature datalogger and software – ideal for educational programmes and accurate reporting.Power sieve for refining end product increasing product usage. |

https://www.youtube.com/watch?v=dEA7n0R1NPc