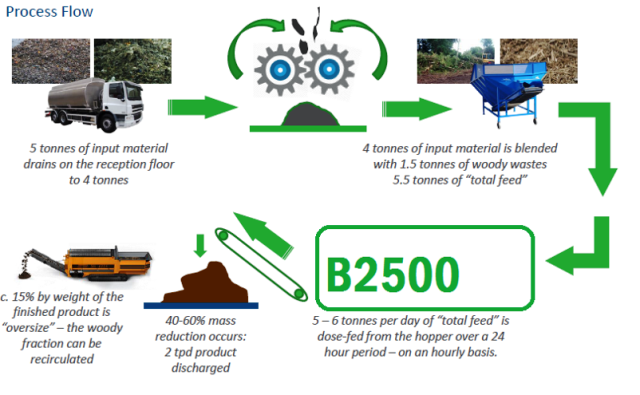

In vessel composting plant 5-7 tons/day.

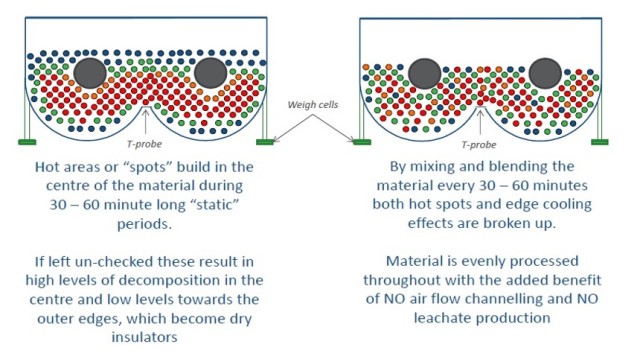

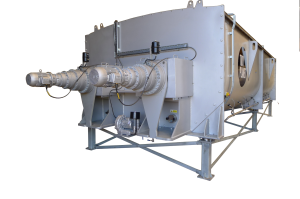

The B2500 Rocket Composter has been uniquely designed and patented.The system comprises of a “Double U” shaped hull with twin longitudinal shaft configuration.This unique arrangement allows much greater mixing of materials which in turn leads to a more uniform degradation.The design also then impacts on running costs and maintenance as we are able to provide a system with no internal support mechanisms for the shafts.

Composting process

- Woody / sewage wastes are shredded and mixed together

- A wheeled loader or similar will be needed to mix / load the wastes

- A heavy duty shredder may be required depending on the woody wastes provided

- The operator will need to be trained on equipment but also in the management of the incoming feedstock and what requires / does not require mixing and shredding

- The mixed sewage / wood are loaded by operator into a bulk feed / loading hopper

- The loading hopper belt feeds directly into the composting unit

- The feed rate is 24/7 and determined by the software governing the composting vessel, the system will “feed itself” throughout the day without manual operator intervention

- The main hopper may need filling only once or twice per day

- The Vessel is a continual process system, loaded with wastes daily that gradually process along the unit, being pushed by the weight of the fresh incoming wastes while the shafts agitate the mix

- The material will reduce by weight byc:40% in the process and material that has resided for c:8 days will be automatically ejected by screw discharge onto a belt and into a stockpile

- All this is PLC Controlled

- The vessel is linked to odour control system

- The vessel is equipped with air injection and air extraction

- The daily compost product will be c:2tonne per composting vessel this will need moving x 2 by loading shovel to maturation bays

- After c: 2 week stabilising the compost will be moved into a second adjacent maturation bay

- After a further 2 weeks the product can be refined further before re-use

- Screening equipment will be required / trommel

- Operator training will be required

- Screening will be x 1 every 2 weeks

Why use B2500?

- High temperatures (+60DegC) achieved to ensure pathogen kill

- Minimal footprint for equipment – minimal building space required

- Minimal labour requirements – low operator interaction with equipment

- Enclosed process – no attraction to birds / vermin

- Bio-filtration on site – vented gases are processed through special organic medium to control / eliminate odours

- Simple monitoring of process / adaption of process from “desktop”

- Recognised / regulated technology in Europe for the treating of organic wastes

- Produces sterile biologically degraded material that can be used as compost / soil improver

TECHNICAL SPECIFICATIONS

| Size (mobile) Length | 10000mm |

| Width | 4000mm |

| Height | 2500mm |

| Capacity | 6-7 tn per day |

| Motor | 2*11 kW |

| Power Requirement | Three-phase 415-volt, 2*50 amp |

| Average Power Consumption | 43 kWh per day with air handling |

| Heater Element | optional |

| Temperature Recording | 8 channel recorder and software |

| Air extraction & Ventilation | Included |

| Housing Requirement | Hard standing (non-porous) |

| Options | Air injection, biofiltration, odour management, pre – shredder, loading hopper, end product screening. |