Disposing of cut grass resulting from the maintenance of sport facilities is a severe problem for the competent authority. The technology of InVessel composting is the solution.

The ideal way to handle all organic waste and cut turf is composting. The compost produced is a soil improvement for all green areas.

The incorporation of compost not only enriches the soil with minerals, but also increases its organic matter (Greek soils are very poor in organic matter) and beneficial microbial populations. These microbial populations are responsible for breaking down complex compounds into simple ones, so they can be absorbed by the root system of plants. Simply put, the need for lubrication is reduced and the soil is being purged with the use of chemical fertilizers. Last but not least, compost’s contribution to water retention is significant due to his high water capacity.

Summing up, the benefits of the compost produced by the cut turf of the court are:

- Decrease of the water needs of the garden.

- Reduction of chemical fertilizers.

- Reduce the cost of garbage collection.

- Purge of the soil and increased microbial flora.

- Added Value

- Advertising preeminence and competitive advantage.

In Vessel composters can produce immature compost in just 14 days from the day of loading. Immature compost needs another two more weeks of maturing in open space without any other process.

As mentioned above, it can compost all organic waste produced from kitchens, restaurants and mainly gardens as well as domesticated animals’ droppings.

Process with a very low operating cost as it requires just 30Kwh per week. Easy monitoring of the temperature through a 4-channel recording system. Ability to retrieve graphs via computer and adjust composting parameters. Possibility of wireless tracking of the thermo-diagrams.

The composting of the cut grass is an easy process that produces easily compost of excellent quality, as it mixes 3 parts of grass with 1 part of wood (shredders, chips, etc ).

This technology has been tested and used in similar applications around the world. Below are photos of the produced compost:

- Composting grass and prunings in New York.

- Composting grass with wood chips and coffee grounds in portugal.

- Composting grass with pine tree bark and leaves.

- Composting grass with horse manure in UK.

The composting unit is of continuous flow and loading, which means that a continuous feed is required by the responsible operator.

There are alternatives and loading automats with either buckets or fully automated units including a feed hopper with a stirrer and a transfer belt to the composter.

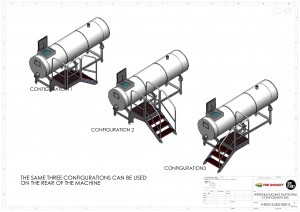

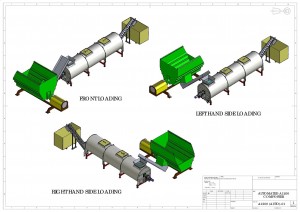

Below are presented alternative installation options with automated or non automated composting systems (Rocket):

- A900 composting unit with loading platform

- Automated loading system with hopper and conveyor belt

The ZeroWaste goal in the court maintenance is now feasible.