In a central Hotel in Athens with over 900 beds has been installed a dehydrating food waste unit and a mechanical composter for the produced material.

The problem that had to be addressed was the management of organic waste with the aim of diverting it from landfill. The management of the hotel sought to improve its greenhouse management and environmental awareness with the purpose of attracting customers as well as reducing CO2 emissions.

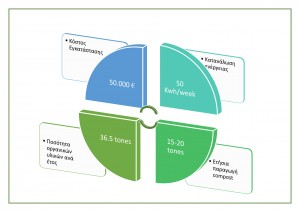

The chosen solution consists of 4 stages.

In the first stage was conducted an integrated waste management study by expert consultants for waste management of the company QAdvisors. The purpose of the study was to evaluate the current situation, which identified the sources, the different categories and the quantities of waste coming from different parts of the hotel. A techno-economic evaluation was also carried out, identifying sustainable actions and the necessary waste management equipment.

In the second stage and basis of the study was organized the sorting of the organic material in separate bins and the training of the personnel so that the collection of the waste takes place in different streams. In this way, apart from the separate collection of the organic waste, a significant increase in the sorting of recyclable materials has been achieved, which can provide a small revenue for the company.

The third stage concerned the reduction of the volume and weight of organic waste. This was accomplished by installing DEHYDRA BENCH dehydrating unit. This unit consists of a powerful waste bin which mashes all organic waste which is then led to a centrifugal unit to make the solids separate from the liquids. The fluids are removed through the drainage system while the solid residue is concentrated in special containers. In this way the volume and weight of organic waste is reduced from 50% to 70%. The process is shown below.

In the fourth and final stage of the waste management, the produced material is led to a closed-loop mechanical composting unit, the ROCKET in vessel composter, where after 14 days, immature compost is produced.

Dehydration is a prerequisite for the composting process because micro-slicing increases the contact surface of micro-organisms while reducing the moisture content of waste to 50%, which is ideal for proper composting. When adding organic wastes, the corresponding amount of wood (chopped branches, wood chips or any other form of wood) should always be added, due to the need of a carbon source for the composting micro-organisms.

Once the material enters the ROCKET chamber, the composting process is undertaken by aerobic microorganisms.

The process is aerobic and occurs in 4 stages with different temperatures. The 4-channel recorder is connected to a computer and produces the temperature graphs from where the information is received for the course of the process.

Temperatures reach up to 80 degrees ensuring the hygienic state of the produced compost by potentially dangerous pathogens.

The final product is transferred in special bags and needs to stay for another 2 weeks outdoors to mature and be ready for use.